| System width (mm) | 5500 mm |

| System length (mm) | 13600 mm |

| Drums- Max. weight capacity (kg) | 10000 kg |

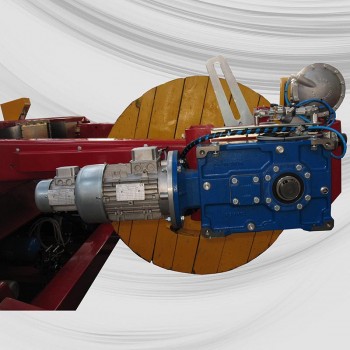

| Total power (kW) | 12 KW |

| Power usage (kW) | 5 KW |

| Min./max. rpm (rpm at drum) | 0-80 |

| Speed max. (m/min) | 0-80 m/min |

| Max. winding torque (N/m) | 2760 N/m |

| Size tolerance (±%) | ±0,5% |

LINAP-100/30-BA LOW PERFORMANCE - AVERAGE CYCLE TIME (LOADING-UNLOADING-WINDING 300m) 24 MIN

LINAP-100/30-BA

Technical data sheet

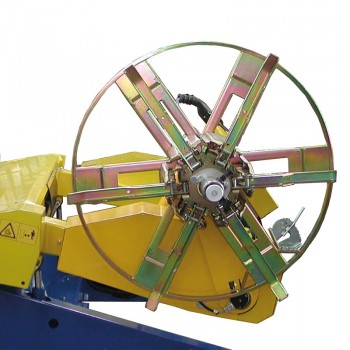

| Winder - Max. drum diameter (mm) | 3000 mm |

| Winder - Max. drum width (mm) | 2000 mm |

| Winder - Min. drum diameter (mm) | 800 mm |

| Winder - Min. drum diameter (mm) | 400 mm |

| Payoff - Max. drum diameter (mm) | 3000 mm |

| Payoff - Max. drum width (mm) | 2000 mm |

| Payoff - Min. drum diameter (mm) | 600 mm |

| Payoff - Min. drum diameter (mm) | 400 mm |

Accessories included

Accessories on request

Item no. OA-10Q-100/OM/MID-LINAP

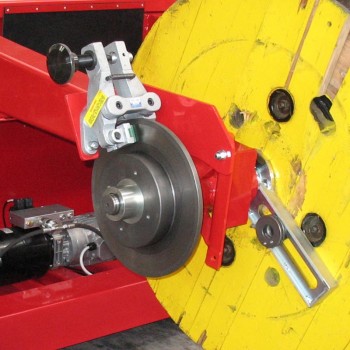

Electronic precision counter with display

MID EUROPEAN TYPE APPROVAL

ADD TO QUOTE

DETAILS