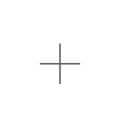

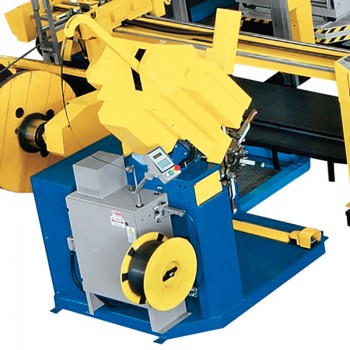

| Winder - Max. drum diameter (mm) |

1600 mm |

| Winder - Max. drum width (mm) |

1130 mm |

| Winder - Min. drum diameter (mm) |

600 mm |

| Winder - Min. drum diameter (mm) |

300 mm |

| Coiling station - Max. coil diameter (mm) |

890 mm |

| Coiling station - Max. core diameter (mm) |

520 mm |

| Coiling station - Min. core diameter (mm) |

320 mm |

| Coiling station - Max. coil width (mm) |

200 mm |

| Coiling station - Min. coil width (mm) |

90 mm |

| Payoff - Max. drum diameter (mm) |

1600 mm |

| Payoff - Max. drum width (mm) |

1130 mm |

| Payoff - Min. drum diameter (mm) |

600 mm |

| Payoff - Min. drum diameter (mm) |

300 mm |